Bottom price Weigh Belt Conveyor - JJ-LIW BC500FD-Ex Dripping System – JIAJIA

Bottom price Weigh Belt Conveyor - JJ-LIW BC500FD-Ex Dripping System – JIAJIA Detail:

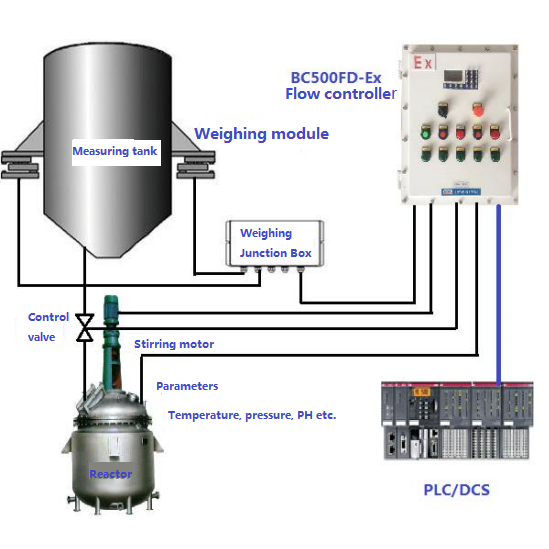

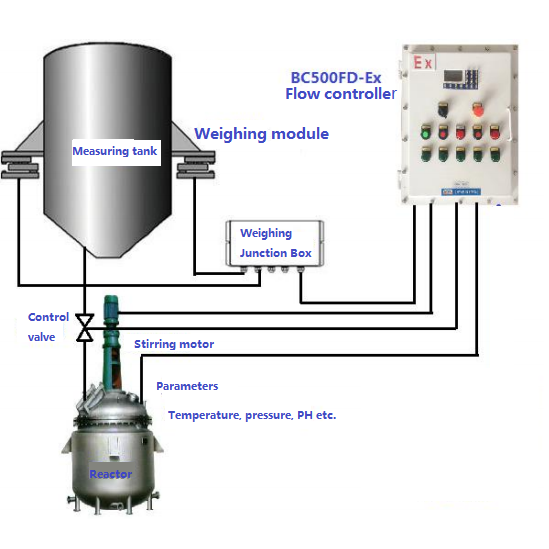

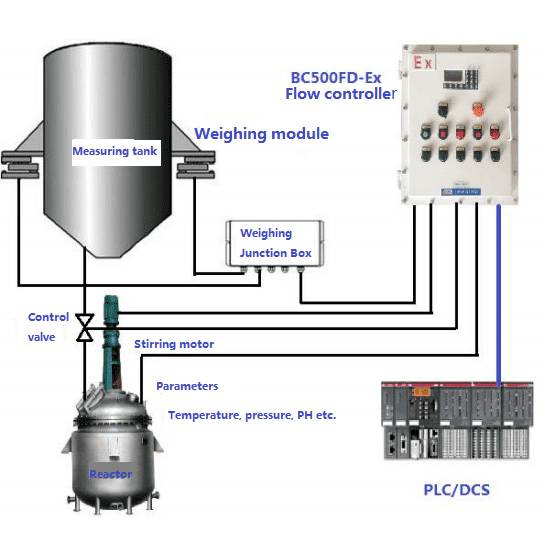

Function principles

The meter controller collects the weight signals of the measuring tank in real-time

Convert the weight per unit time into an instantaneous flow

PID controller calculates the instantaneous flow rate and the preset value

According to the PID algorithm results, the meter controller outputs 4-20mA analog signals to the regulating valve/inverter to make precise flow control

At the same time, the meter controller accumulates the weight of the material flowing out of the measuring tank. When the accumulated value is equal to the set value, the meter controller closes the valve/inverter and stops the dripping.

Features

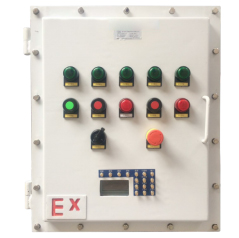

Highlight display interface, simultaneously display instantaneous flow and cumulative total

Automatic feeding function

Remote, local switching, and manual and automatic control

Comprehensive status monitoring and chain alarm function

Real-time monitoring of sensor load, convenient for maintenance and troubleshooting

Can coordinate with DCS/PLC through the data bus

Standard RS232/485 dual serial ports, MODBUS RTU communication

Extendable a 4~20mA input and a 4~20mA output Optional Profibus DP interface

Features

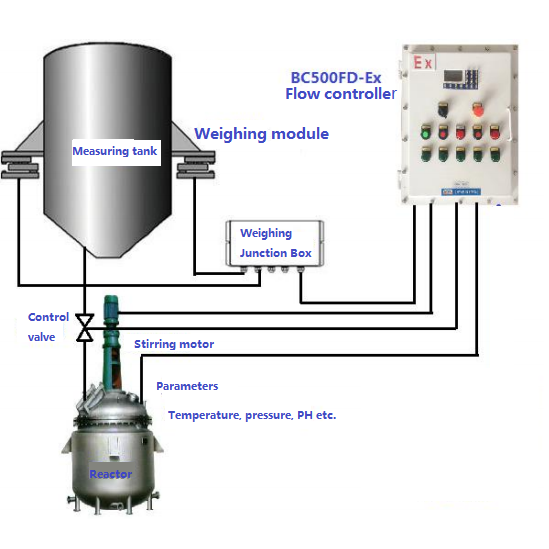

Case 1: Weighing flowmeter

1. The weighing method is not affected by temperature, density, installation method, etc.

2. High measurement accuracy

3. No contact with materials, no cross-infection

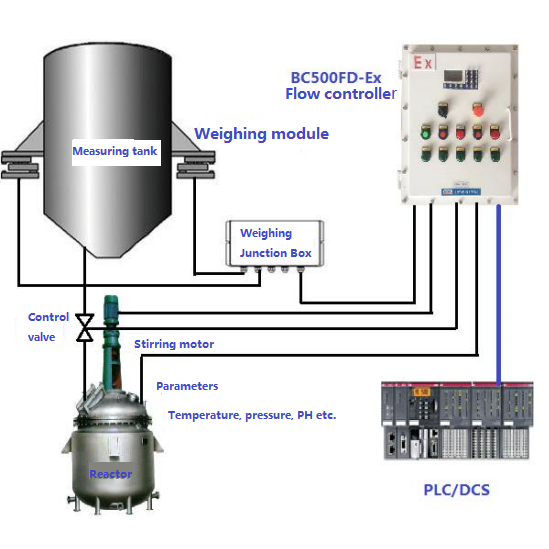

Case 2: Automatic control of dripping by the instrument

1. Automatic drip control of the instrument

2. Quick setting of process parameters

3. On-site operation display, simple and intuitive

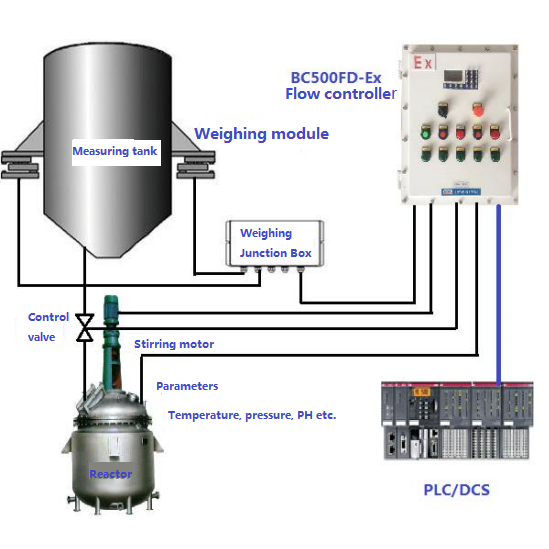

Case 3: Meter metering flow, DCS control dripping

1. The weighing method is not affected by temperature, density, installation method, etc.

2. The meter directly provides flow data, and DCS controls the process

3. Fast sampling frequency and high measurement accuracy

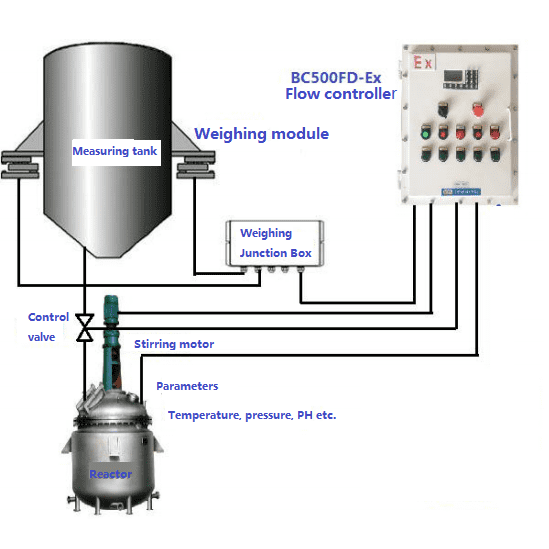

Case 4: DCS instruction, meter automatically controls dripping

1. Automatic dripping control

2. The instrument participates in the process

3. Reduce the cost of PLC/DCS software and hardware

Specification

| Enclosure |

Cast Aluminum |

| Run Mode |

Constant feeding, Material level Balancing, Batch feeding |

| Signal Range |

-20mV~+20mV |

| Max. Sensitivity |

0.2uV/d |

| FS Drift |

3ppm/°C |

| Linearity |

0.0005%FS |

| Flowrate Unit |

kg/h, t/h |

| Dec.point |

0, 1, 2, 3 |

| Control Mode |

Zone Adj. / PID Adj. |

| Max Quantity |

<99,999,999t |

| Display |

128×64 Yellow-Green OLED display |

| Keypad |

16 Flat switch membrane with tactile-feel keys; polyester overlay |

| Discrete I/O |

10 Inputs; 12 Outputs(24VDC @500mA with over-load protection) |

| Analog Output |

4~20mA/0~10V |

| USART |

COM1: RS232;COM2: RS485 |

| Serial Protocol |

MODBUS-RTU |

| Power Supply |

100~240VAC,50/60Hz, <100mA(@100VAC) |

| Operating Temperature |

–10°C ~ +40°C,Relative humidity:10%~90%,non-condensing |

Product detail pictures:

Related Product Guide:

Why is there an error in weight calibration?

New weights and their correct classification method

The key to our success is "Good Products Good quality, Reasonable Value and Efficient Service" for Bottom price Weigh Belt Conveyor - JJ-LIW BC500FD-Ex Dripping System – JIAJIA , The product will supply to all over the world, such as: Nigeria, Ghana, Uruguay, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We've got tightened inspection for quality of product.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.