Factory Supply Conveyor Belt Weighing Systems - JJ-LIW Loss-In-Weigh Feeder – JIAJIA

Factory Supply Conveyor Belt Weighing Systems - JJ-LIW Loss-In-Weigh Feeder – JIAJIA Detail:

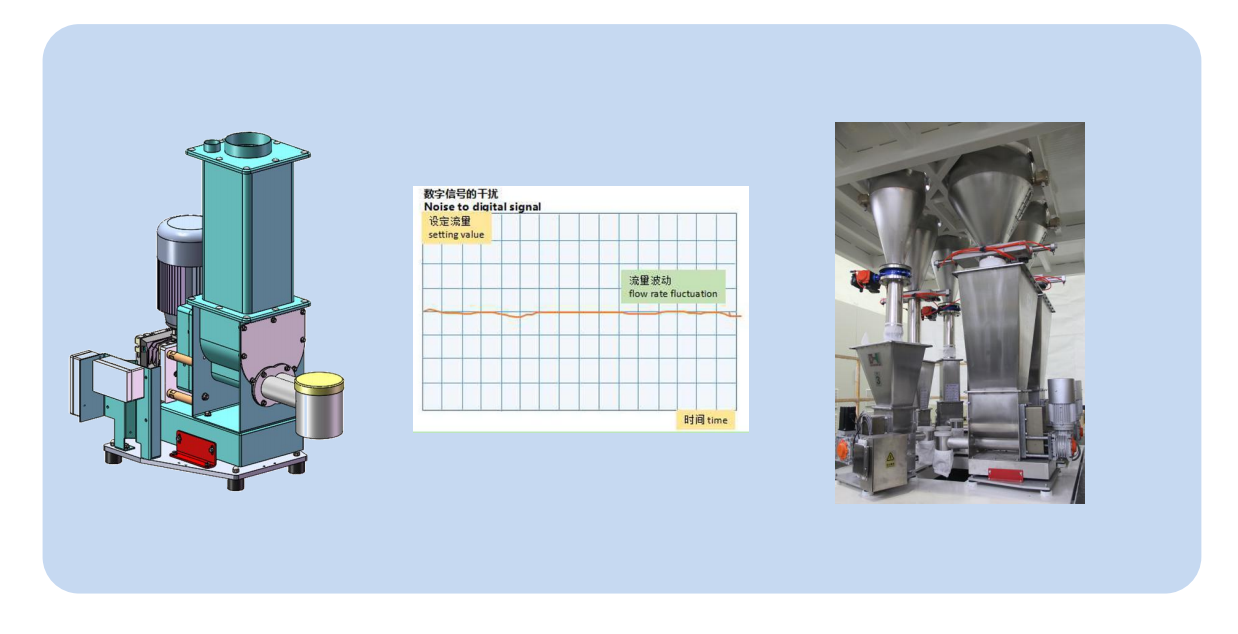

Function principles

LIW series loss-in-weight flow metering feeder is a high-quality metering feeder designed for the process industry. It is widely used for continuous constant flow batching control and precise batch control process of granular, powder, and liquid materials at industrial sites such as rubber and plastics, chemical industry, metallurgy, food, and grain feed. LIW series loss-in-weight flow metering feeder is a high-precision feeding system designed by mechatronics. It has a wide feeding range and can meet a variety of applications. The entire system is accurate, reliable, easy to operate, easy to assemble and maintain, and easy to use. LIW series models cover 0.5~22000L/H.

Features

Choice of solid and liquid feeding models

Fast and accurate continuous flow balance control

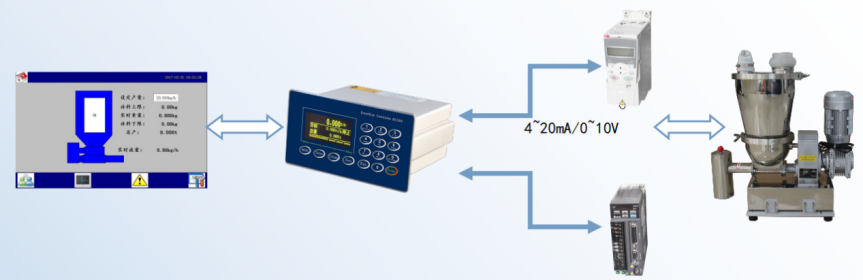

Working mode: 1. Constant flow control; 2. Quantitative feeding control under constant flow

4~20mA or 0~10V adjustable output (optional)

Double closed-loop PID control system

Support remote, local switching, and manual and automatic control

Comprehensive status monitoring and chain alarm function

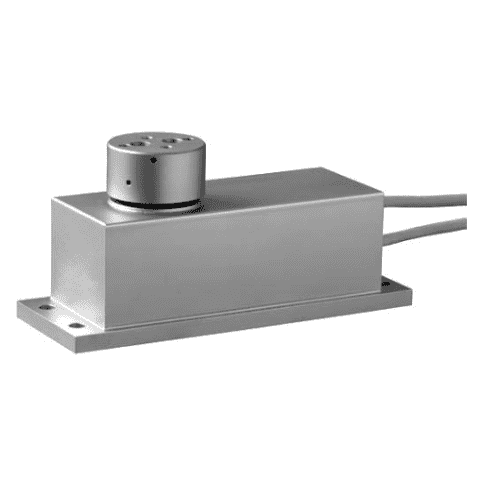

Real-time monitoring of sensor load, convenient for maintenance and troubleshooting

Fast screw replacement

Adopt 24-bit high-precision SIGMA-DELTA AD conversion chip, 300Hz effective output rate

The maximum display division number is 100000

2.71”128×64 dot-matrix OLED display; Chinese and English menu interface. The maximum display character height is 0.7”, optional touch-screen man-machine interface

Standard RS232 and RS485 dual isolated serial ports, MODBUS RTU communication protocol

Optional Profibus DP and Profinet industrial bus

Control accuracy: within ±0.2%~0.5% (according to different materials and ranges)

Feeding range: 0.5~10000kg/h (depending on different model series)

Power supply: 380VAC/50Hz

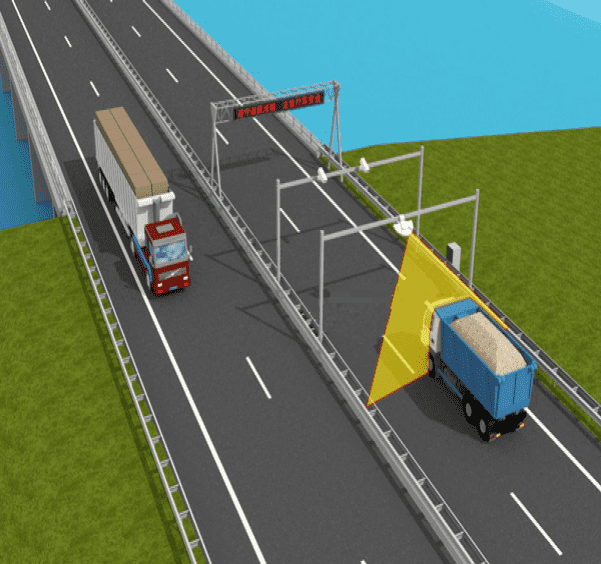

Principles and Solutions

Case 1:Independent single-component weightlessness scale control system

Case 2:Two-component weightlessness scale control system

Case 3:Multi-component weightlessness scale control system

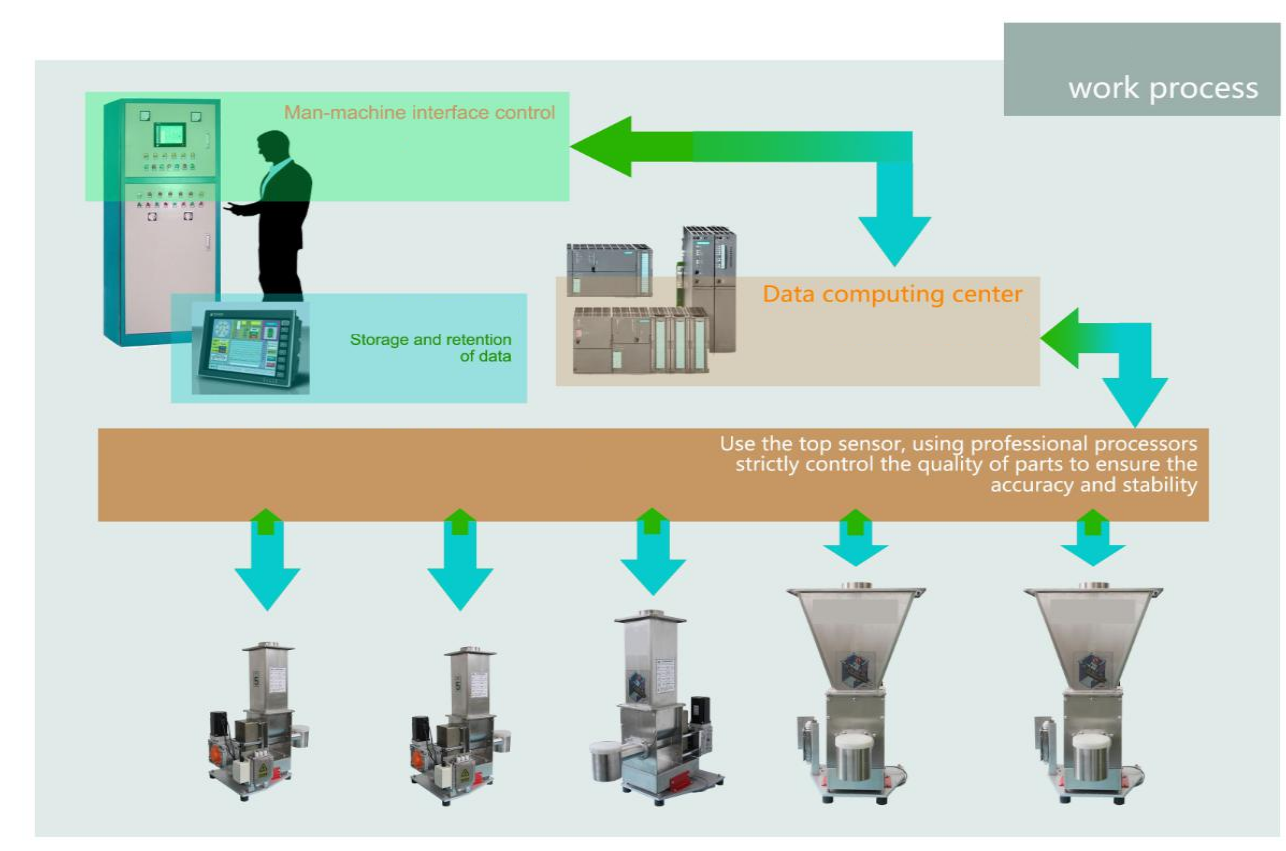

Work Process

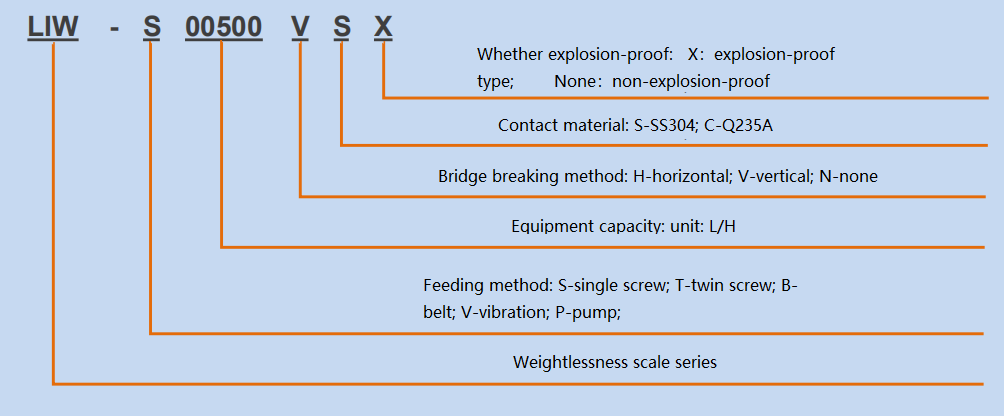

Model Specification

Order description

1. The scope of supply of this product’s standard configuration includes:

a) Mechanical structure part: scale body, metering, conveying device,

bracket, geared motor, etc.

b) Weighing control part: weightless metering controller, sensor, inverter/servo controller, low-voltage electrical components, and control box

2. The standard cable length is 10 meters, and the excess part is priced by length.

3. The weightless scale running in a single machine can be equipped with a 7′touch screen.

4. Provide before ordering: material bulk density, shape, output, and special requirements.

5. For materials with poor fluidity, samples must be submitted to the technical department of our company for verification and confirmation before the order can be signed.

Product detail pictures:

Related Product Guide:

New weights and their correct classification method

Why is there an error in weight calibration?

We usually perform being a tangible workforce making sure that we will give you the most beneficial excellent plus the finest selling price for Factory Supply Conveyor Belt Weighing Systems - JJ-LIW Loss-In-Weigh Feeder – JIAJIA , The product will supply to all over the world, such as: venezuela, Israel, Moldova, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The items to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.