Truck Scales

-

Axle Load Type Dynamic Truck Scale (Eight module)

1. System features

It can weigh vehicles passing at low speed and automatically determine whether the vehicle weight or axle weight is overloaded;

It can detect the number of axles, axle groups, axle weight and vehicle weight of the vehicle;

It can form complete vehicle weighing information, including axle type, axle weight, axle group and total weight;

It can transmit weighing information to the computer through the data interface;

The core part of the system adopts mature and reliable equipment, all of which adopt modular design, easy to maintain and expand, ensuring the high reliability of the system.

The system software is mature, reliable, and the data is complete and effective, and it can be fully shared, effectively improving work efficiency and eliminating various management loopholes to the greatest extent.

2. System composition

The overload and overlimit system consists of ZDG eight-module dynamic axle weighing scale, control instrument, infrared vehicle separator, weighing platform wheel axle identifier, control cabinet, (optional equipment: license plate recognition system, LED large screen display system, voice prompt system, vehicle guidance system, industrial computer, ticket printer, UPS uninterruptible power supply, overload and overlimit detection system software, monitoring system) and other accessories and cables. -

Axle Load Type Dynamic Truck Scale (four-modules)

1. System features

It can weigh vehicles passing at low speed and automatically determine whether the vehicle weight or axle weight is overloaded;

It can detect the number of axles, axle groups, axle weight and vehicle weight of the vehicle;

It can form complete vehicle weighing information, including axle type, axle weight, axle group and total weight;

It can transmit weighing information to the computer through the data interface;

The core part of the system adopts mature and reliable equipment, all of which adopt modular design, easy to maintain and expand, ensuring the high reliability of the system.

The system software is mature, reliable, and the data is complete and effective, and it can be fully shared, effectively improving work efficiency and eliminating various management loopholes to the greatest extent.

2. System composition

The overload and overlimit system consists of ZDG four-module dynamic axle weighing scale, control instrument, infrared vehicle separator, weighing platform wheel axle identifier, control cabinet, (optional equipment: license plate recognition system, LED large screen display system, voice prompt system, vehicle guidance system, industrial computer, ticket printer, UPS uninterruptible power supply, overload and overlimit detection system software, monitoring system) and other accessories and cables. -

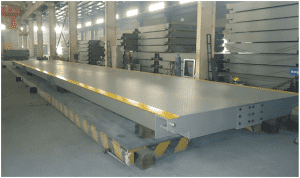

PIT TYPE WEIGHBRIDGE

General Introduction:

Pit type weighbridge is most suitable for places with limited space like non-hilly areas where the construction of pit is not much expensive. Since the platform is in level with the ground, vehicles can approach the weighbridge from any direction. Most public weighbridges prefer this design.

Main features are the platforms are connected to each other directly, no connection boxes between, this is an updated version based on old versions.

The new design performs better in weighing heavy trucks. Once this design is launched, it becomes popular immediately in some markets, it is engineered to heavy, frequent, day- to -day use. Heavy traffic and over-the-road weighing.

-

HOT DIPPED GALVANIZED DECK PIT MOUNTED OR PITLESS MOUNTED

Specifications:

* Plain plate or chequered plate is optional

* Composed of 4 or 6 U beams and C channel beams, robust and rigid

* Middle dissected, with bolts connection

* Double shear beam load cell or compression load cell

* Width available: 3m,3.2m,3.4m

* Standard length available: 6m~24m

* Max. Capacity available: 30t~200t

-

CONCRETE WEIGHBRIDGE

Concrete deck scale for weighing over-the-road legal vehicles.

It is a composite design that uses concrete deck with a modular steel framework. The concrete pans come from the factory ready to receive concrete without any field welding or rebar placement required.

pans come from the factory ready to receive concrete without any field welding or rebar placement required.

This simplifies installation and ensures the overall quality of the deck.

-

HIGHWAY/BRIDGE LOADING MONITORING AND WEIGHING SYSTEM

Establish non-stop oveload detection point, and collect vehicle information and report to the information control center through hig-speed dynamic weighing system.

It could recognize vehicle plate number and on-site evidence collection system to notify the overloaded vehicle through comprehensive management system of scientifically control of overlad.

-

Axle scale

It is widely used in the weighing low-value materials in transportation, construction, energy, environmental protection and other industries; trade settlement between factories, mines and enterprises, and vehicle axle load detection of transportation companies. Quick and accurate weighing, convenient operation, simple installation and maintenance. Through weighing the axle or axle group weight of the vehicle, the whole vehicle weight is obtained through accumulation. It has advantage of small floor space, less foundation construction, easy relocation, dynamic and static dual use, etc.

-

PITLESS WEIGHBRIDGE

With steel ramp, eliminates the civil foundation work or concrete ramp will be also works, which only need few foundation work. Only a well leveled hard and smooth surface is required. This process accrue saving in cost of civil foundation work and time.

With steel ramps, the weighbridge can be dismantled and re-assemble within a short span of time, it can be constantly relocated near to area of operation. This will help enormously in reducing lead distance, reduction of handling cost, manpower, and appreciable improvement in productivity.